What is neutral clear silicone?

Why Choose Neutral Clear Silicone? Top Reasons & Benefits

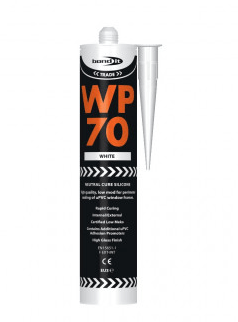

Neutral clear silicone is a type of sealant commonly used for various applications around the house or for construction purposes. is a one-part silicone sealant that cures by reacting with moisture in the air.

Definitions of it

- Neutral cure: Unlike some other silicone sealants, neutral cure silicone doesn’t release any vinegar odour during the curing process. This makes it ideal for use in areas with poor ventilation or around materials that could be sensitive to acidic fumes.

- Clear: As its name, it’s transparent, making it a good choice for applications where you want the sealant to be virtually invisible. This is particularly useful for sealing around clear materials like glass or for creating a clean finished look.

- Silicone: Silicone is a versatile material known for its flexibility, weather resistance, and adhesion to various surfaces.

Uses of Neutral Clear Silicone

Neutral clear silicone boasts a wide range of applications by its unique properties of adhesion, flexibility, and weather resistance.

Neutral clear silicone boasts a wide range of applications by its unique properties of adhesion, flexibility, and weather resistance.

- Sealing Bathrooms and Kitchens: a most common use of Neutral clear silicone which is perfect for sealing around sinks, bathtubs, showers, countertops, and backsplashes. It creates a watertight barrier that prevents moisture from seeping behind these fixtures and causing damage.

- Window and Door Installation: Neutral clear silicone is a great choice for sealing gaps around windows and doors. This ensures they are properly insulated, reducing drafts and preventing air and water infiltration.

- Filling Cracks and Gaps: Neutral cure silicone can effectively fill floor tiles, walls, and creating a smooth and finished look.

- Stick down Applications: Besides sealing, neutral cure silicone can act as an sticking for various materials like glass, metal, tile, and certain plastics. This can be useful for small repairs or adhering decorative elements.

- Electrical Applications: Specific types of neutral cure silicone are formulated to be electrically insulating. These are suitable for sealing around electrical components where a non-conductive material is required.

- Marine Applications: Due to its excellent resistance to water and harsh weather conditions, neutral cure silicone can be used for sealing boats and other marine equipment.

- DIY objects and electrinics: The versatility of neutral clear silicone makes it a handy tool for various DIY projects. You can use it for sealing around appliances, ventilation ducts, or even for crafting projects that require a clear and flexible adhesive.

Features of Neutral Clear Silicone

Due to its component of silicone, Neutral clear silicone offers a wide range of features and properties making neutral clear silicone is the right choice for your sealing or adhesive needs

Properties:

- Temperature resistance: Neutral cure silicone generally has a good temperature resistance range, typically able to withstand -40°C to 150°C (-40°F to 300°F) after curing. This makes it suitable for both indoor and outdoor applications.

- Movement capability: Due to its silicone nature, it remains flexible after curing. This allows it to accommodate slight movements or vibrations between surfaces without cracking. This is particularly important in applications like sealing around expansion joints.

- Chemical resistance: Neutral cure silicone offers good resistance to many common chemicals, including water, moisture, UV rays, and some cleaning solutions. This ensures a durable and long-lasting seal.

- Shelf life: Typically, unopened cartridges of neutral cure silicone have a shelf life of around 12 to 18 months, depending on the brand and storage conditions.

- Flexibility: It remains pliable after curing, allowing it to accommodate slight movements or vibrations between surfaces without cracking. This is crucial for sealing around areas prone to expansion and contraction.

- Weather Resistance: It can withstand a wide range of temperatures, UV rays, and moisture, making it suitable for both indoor and outdoor applications.

- Adhesion: It bonds well to various surfaces, creating a strong and durable seal.

- Odorless: Neutral cure silicone eliminates the unpleasant vinegar odor associated with other silicone sealants, making it more pleasant to use indoors.

- Fast Curing: While cure times can vary by brand, neutral cure silicone generally cures within 24-48 hours, allowing you to complete your project faster.

- Long Shelf Life: Unopened cartridges typically have a shelf life of around 12-18 months, depending on the brand and storage conditions.

- Paintable: Once fully cured, some types of neutral clear silicone can be painted over, allowing you to further enhance the finished look.

- Non-toxic (when cured): This makes it safe for use around aquariums, terrariums, and even in applications involving food contact surfaces (check product labels for specific certifications).

Curing and Drying of Neutral Clear Silicone

There are 2 phase for using Neutral Clear Silicone

1-Drying:

This is the initial stage where the exposed surface of the applied silicone forms a skin.

It happens relatively quickly due to the evaporation of solvents present in the silicone.

Drying times can vary depending on factors like:

- Humidity: Higher humidity slows down drying as there’s less moisture in the air for the solvent to evaporate into.

- Airflow: Good airflow around the applied silicone promotes faster drying.

Thickness of the application: A thin bead will dry faster than a thicker one.

2-Curing:

This is the crucial stage where the silicone undergoes a chemical reaction to transform into a flexible and waterproof seal.

During curing, the silicone reacts with moisture in the air (a process called hydrolysis) to form siloxane bonds. These bonds are responsible for the sealant’s strength, flexibility, and water resistance.

Curing times are generally much slower than drying times and can be influenced by several factors:

- Thickness of the application: Thicker applications take longer to cure completely as the moisture has to penetrate deeper into the silicone.

- Humidity: Higher humidity levels accelerate curing as there’s more moisture available for the reaction. Ideally, humidity should be between 40% and 60% for optimal curing.

- Temperature: Warmer temperatures generally promote faster curing, while colder temperatures slow it down.

Typically, neutral clear silicone can develop a dry skin within 30 minutes to an hour under normal room temperature and humidity conditions.

Maintenance and Care for Neutral Clear Silicone

Here’s a guide on maintaining and caring for neutral clear silicone to ensure it continues to perform well and extend its lifespan:

- Cleaning: Regularly wipe down the silicone with a damp cloth to remove dirt, dust, and surface grime. You can use a mild soap solution for tougher cleaning tasks. Avoid harsh chemicals or abrasive cleaners that could damage the silicone.

- Mold Prevention: Mold and mildew can grow on silicone surfaces in areas with high moisture exposure, like bathrooms and kitchens. To prevent this:

- Ensure proper ventilation to reduce humidity levels.

- After cleaning the silicone, allow it to dry completely.

- Consider using a mold-killing solution specifically designed for silicone applications (refer to manufacturer’s instructions for safe use).

Maintaining the Seal:

- Inspection: Periodically inspect the silicone sealant for signs of wear and tear, such as cracks, peeling, or loss of adhesion.

- Repairing Minor Damage: For small cracks or gaps, you might be able to repair them by cleaning the area thoroughly and applying a fresh bead of neutral clear silicone. Ensure the existing silicone is compatible with the new one.

- Replacement: If the silicone is significantly damaged, cracked, or losing adhesion, a complete replacement might be necessary. This would involve removing the old silicone carefully, cleaning the surface, and applying a fresh bead of new sealant.

Comparison with Other Types of Silicone

Neutral clear silicone is a versatile choice, but it’s not the only player in the silicone game. Here’s a breakdown of how it compares to other common types of silicone sealants:

Neutral Cure Silicone (Clear)

Features: Doesn’t emit vinegar odor – Transparent – Flexible Weather resistant – Good adhesion on various surfaces.

Advantages: sealing around various surface.

Disadvantages: Doesn’t always adhere well to porous materials – Slower cure time compared to some other types

Acetoxy Cure Silicone (Clear or Colored)

Features :Releases vinegar odor during curing-* Can be transparent or colored – Flexible – Generally faster cure time than neutral cure.

advantage: General purpose sealing applications (indoor), some outdoor uses depending on the brand .

disadvantages: Vinegar odor can be unpleasan – May not be suitable for some materials sensitive to acidic fumes.

Oxime Cure Silicone (Neutral Cure)

features: Similar to neutral cure silicone, but may offer superior adhesion and performance -Doesn’t emit vinegar odor – Excellent adhesion (various surfaces)- Highly flexible- Weather resistant .

Advantages: High-performance sealing applications where strong adhesion and weather resistance are critical.

Disadvantage Generally more expensive than other types – Curing time might be slower than some acetoxy cures .

Silicone Sealant (Colored)

features: Similar properties to clear silicone but comes in various colors Useful for matching existing aesthetics.

disadvantages: Colored options might have slightly different properties compared to clear ones in terms of flexibility or UV resistance.

advantages: Decorative sealing applications where color matching is important .

Silicone Adhesive

features: Formulated specifically for bonding purposes – Excellent adhesion to various surfaces.

disadvantages: Might not be as effective for sealing applications – May not be as flexible as some sealants.

Advantages: Bonding various materials (glass, metal, tile, some plastics) .

Here are some additional factors to consider when choosing a silicone:

- Surface Compatibility: Always check the label to ensure the chosen silicone is compatible with the surfaces you’ll be applying it to.

- Application: Consider the specific application and whether sealing or adhesion is the primary function.

- Desired Properties: Prioritize features like flexibility, weather resistance, or cure time based on your project needs.

- Odor: Opt for neutral cure silicone if odor is a concern, particularly for indoor applications.

By understanding the different types of silicone and their strengths, you can make an informed decision about the best choice for your project.

Safety Precautions for Using Neutral Clear Silicone

- Surface Compatibility: While versatile, neutral cure silicone might not adhere well to all surfaces, particularly porous ones. Always check the label for recommended applications.

- Surface Preparation: Ensure a clean, dry, and contaminant-free surface for optimal adhesion.

- Curing Time: Avoid disturbing the sealant during its curing time (typically 24-48 hours) to ensure a proper bond.